TTK one-piece bimetallic rare earth copper alloy bearing (bearing bush)

Key words:

Service Hotline:

Category:

TTK one-piece bimetallic rare earth copper alloy bearing (bearing bush)

R & D background

The material and structure of traditional press bearings have been unable to meet the load-bearing strength requirements of the current large amount of pressing, resulting in serious damage to the bearing pad surface, large amount of wear and high scrap rate. However, sugar mills in Southeast Asian countries choose to import bearing products for presses from Australia, France, Japan and other countries. They adopt an all-copper structure and are very expensive to manufacture. After the use of the pressing season, the tile surface is still severely worn.

product description

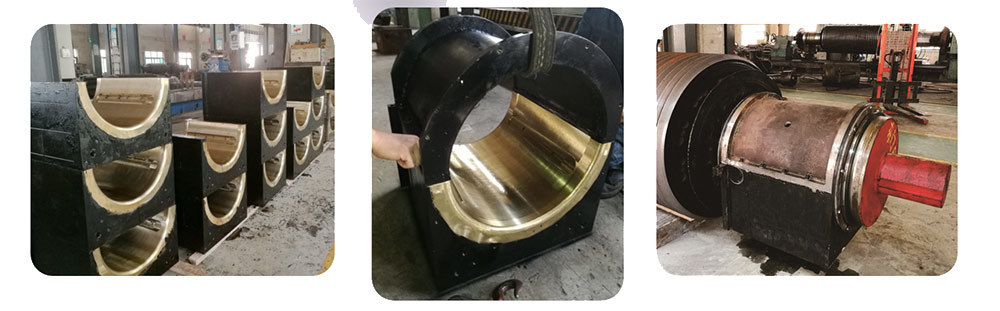

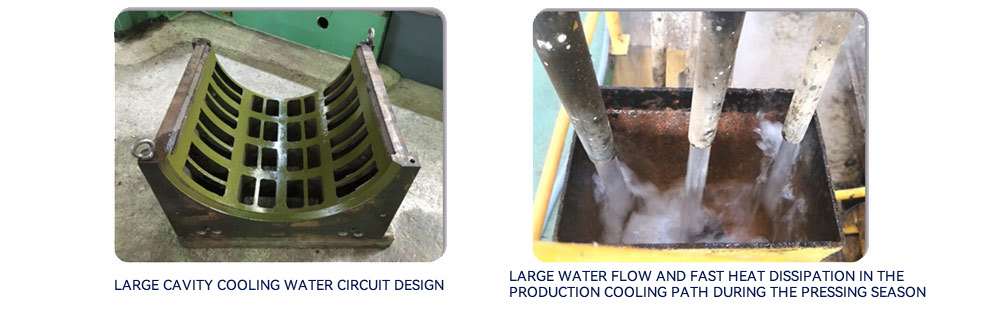

In view of the problems of large amount of wear, low bearing strength, poor performance of metal materials, defects in heat dissipation structure, and lack of sealing protection in the use of press sliding bearings in domestic and Southeast Asian sugar factories, our company has carried out research on the related technologies of press sliding bearings. Using rare earth copper-steel composite bimetallic materials, integrated structure design, large cavity cooling waterway design, fully sealed device process design, and new high-frequency metallurgical cladding technology, the TTK integrated bimetallic press sliding bearing product was developed. It solves the shortcomings of low bearing strength, no sealing device, large amount of wear, cracking of the bearing surface, water leakage and oil leakage, and high maintenance and maintenance costs that exist in the traditional press bearing.

TTK integrated bimetallic press sliding bearing is at the domestic advanced level, and its application in international sugar press equipment is also advanced. It has updated the split bearing that has been used in China for more than 60 years. The product-related technology has reached the domestic advanced level.

Key technologies and innovations

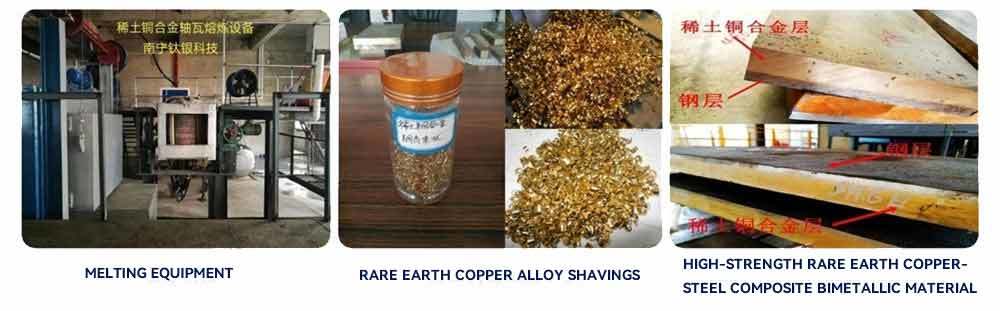

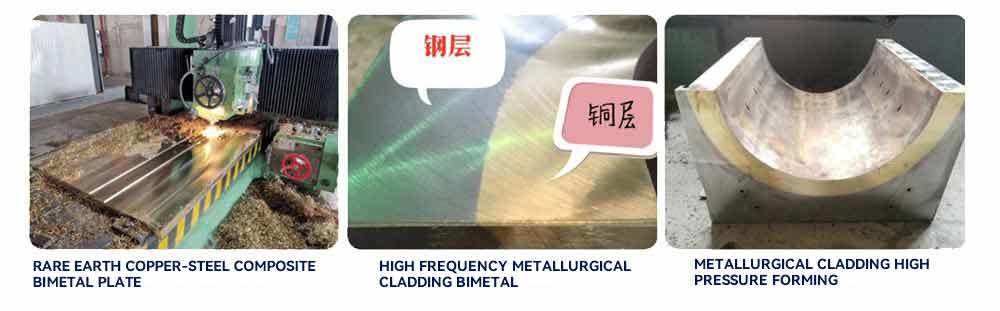

1. High-strength rare earth copper-steel composite bimetallic material. First of all, with copper, aluminum, nickel, rare earth and other raw materials, through a reasonable proportion of the optimal formula, through high temperature smelting, casting molding. The developed rare earth copper alloy sheet and steel are metallurgically bonded by high temperature cladding. The rare earth copper-steel composite bimetal material improves the bearing strength, wear resistance, heat transfer and corrosion resistance of the bearing surface, and meets the requirements of the bearing in harsh environments.

2. Integrated structure design. Using special process technology, the two metals of copper and steel are metallurgically clad at high temperature and high pressure into a whole bearing. The bearing strength is above 580 Mpa, the structure of the copper tile and the steel base is not deformed, and the cladding layer is not cracked.

3. Large cavity cooling water circuit design. The large-cavity wave circulation cooling water circuit design is adopted to effectively accelerate the even distribution of heat, so as to achieve the purpose of rapid cooling. The bearing cooling area reaches 65% of the entire bearing area, which is 13 times larger than the traditional press bearing cooling area.

4. Process design of fully sealed device. After the full sealing device is installed on the journal bearing bush, it prevents the sugarcane juice bagasse from entering the bearing, prevents the free flow of lubricating grease, solves the problem of environmental pollution of grease, and meets the requirements of food hygiene standards in the production site. It can reduce the amount of lubricating grease by more than 30% and reduce production and operation costs.

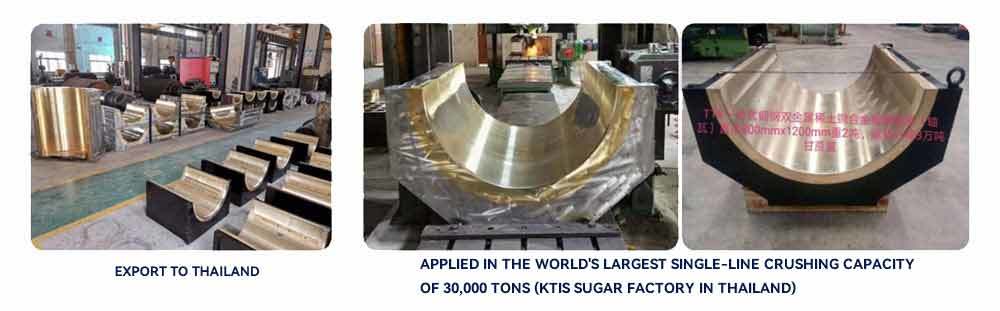

Applications

In foreign markets, Thailand's KTIS Sugar Factory, Puqiao Sugar Factory, TRR Sugar Factory, Utai Sugar Factory, and Ratchaburi Sugar Factory, which have the largest crushing capacity in the world, are also using it with good results and have been highly praised by domestic and foreign sugar industries. Approved. Products gradually enter Southeast Asian countries, actively develop economic partnership with countries along the route, and make due contributions to the national Belt and Road construction.

Funan East Asia Sugar Mill Press Line

Shangshang Sugar Factory Press Line

Thailand KTIS sugar mill pressing line

RELATED PRODUCTS